Application of bottom-discharge vibratory hammer crane-type offshore riprap pile construction —— Offshore bottom-discharge vibratory hammer riprap pile construction of 200,000-ton-class channel project in the central area of Caofeidian Port Area, Tangshan Port

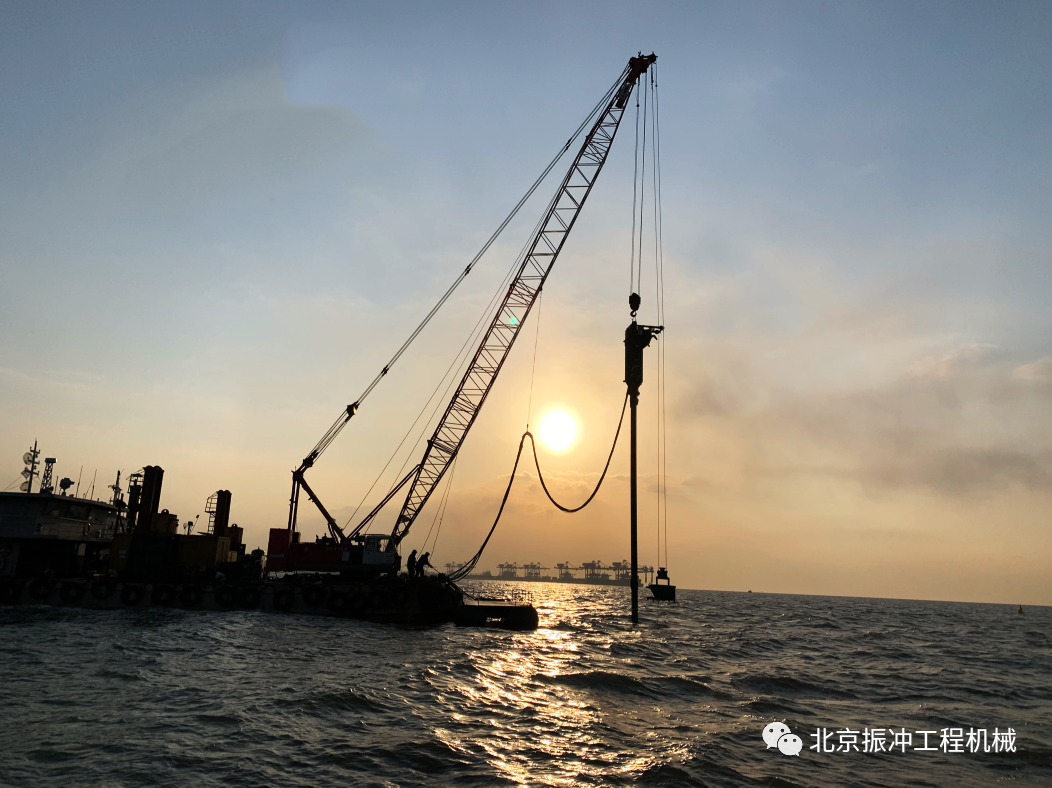

[Overview] In January 2021, crane-type bottom-discharge vibratory hammer equipment, researched and developed by Beijing Zhenchong Engineering Machinery Co., Ltd., was used in offshore operations at Tangshan Caofeidian Port area. The project was the construction of a breakwater head for the 20-ton-class channel expansion project in the harbor basin.

In January 2021, a crane-type bottom-discharge vibratory hammer device, researched and developed by Beijing Zhenchong Engineering Machinery Co., Ltd., was used for offshore operations in the Caofeidian Port area of Tangshan. The project involved the construction of a breakwater head for the expansion of a 20-ton-level channel in the harbor basin.

The construction waters are located near the harbor entrance. On the one hand, the steel wire ropes and anchor chains of conventional flat barges seriously hinder the entry and exit of ships; on the other hand, disturbances from large ships entering and leaving the port, along with waves and currents, make it impossible to use conventional offshore vibratory pile driving methods in this area. Meeting the ground treatment requirements, accurate positioning, and normal backfilling operations presented significant challenges. The limited working space and risks at sea necessitate automated equipment.

The unique vibration compaction of the bottom-discharge vibratory hammer improves soil conditions, and its piping system enables reliable and precise internal material discharge. The one-button pile-driving operation facilitates offshore operations and significantly improves efficiency, making it the ideal choice for this offshore ground treatment project. Beijing Zhenchong Engineering Machinery Co., Ltd., specializing in the vibratory hammer industry for over 40 years, is the developer of China's first bottom-discharge vibratory hammer and a provider of complete sets of equipment, as well as a developer and promoter of automated vibratory hammer construction and quality control technologies throughout the construction process. The company provided complete bottom-discharge vibratory hammer equipment for this project and assisted the China Communications First Highway Engineering Surveying and Design Institute Co., Ltd. with project construction design and related work.

The construction sea area has a harsh climate, with minimum temperatures reaching -25 degrees Celsius. This required the vibratory hammer equipment to be reliable and have a certain degree of cold resistance. The core components of our bottom-discharge equipment are imported from Europe and Japan. After repeated research, we successfully modified a steel-legged pile-driving dredger, solving the problems of precise pile driving and the narrow construction area. Even under these extremely harsh and cold conditions, the construction tasks were successfully completed, with over 3,000 piles driven, totaling 25,000 linear meters.

Main equipment used in the offshore rubble pile foundation treatment construction: bottom-discharge vibratory hammer, crawler crane, material vessel, excavator.

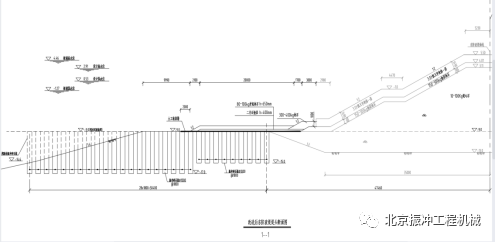

Project operating parameters: starting from -9 meters underwater, pile diameter 1m, working pile depth 15-17m.

Share to

| Related Cases